Backlighting

Bright Ideas

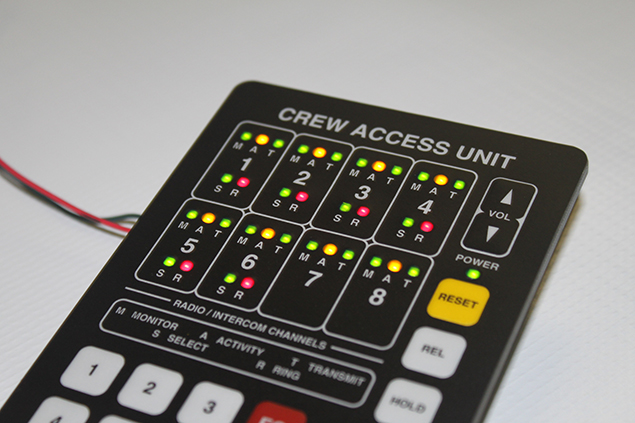

Light has become an integral part of enhancing the Human-Machine Interface (HMI) user experience. Strategically embedding a lighting system into a Membrane Switch, Rubber Keypad or PCB, depending on the method and technique employed, can not only enable, but improve operational awareness in full daylight or lower ambient lighting conditions.For continual ease of reading and identifying keypad legends, for status indicators, warnings or prompts for interaction, informational displays, activity or command confirmations or just for accented style, the inclusion of at least some element of backlighting has always enjoyed highly considerable favor and widespread use among most, if not all industries, and is now nothing short of standard, as the intended application warrants.

Screenprint/DOW Brings Things to Light

The choice of internal lighting components and diffusion elements, if correctly chosen, located and optimally matched both visually and electrically, can ensure that favorable operational conditions, whether in dimming, flashing, momentary or constantly lit states, can be met by minimizing – or in the best cases, eliminating – common problems, such as a hot spot over-concentration of light, mismatching colors or intensities over a series of keys or features, or degradation of tactile or operative response in associated electronics, often solved with proper up-front mechanical design.

The ‘Current’ State of Affairs

Here are the most commonly used and time-tested methods for efficient backlighting of both mobile and stationary equipment control panels, labels and graphic overlays:

LEDs

Light Emitting Diodes (LEDs) are considered Optoelectric components – discrete two-terminal polarized semiconductor devices that emit light when a suitable electrical current is applied to the contacts.

Benefits & Applications

- Available in a nearly endless variety of sizes and shapes – thru-hole with adjustable lead lengths and forms, rounded, flat, or color diffused lenses, easily embedded, thin profile surface-mount, reverse-mount, side-light and more, all in industry standard packages!

- Also used for single indicators, bar graphs, 7-segment or dot matrix displays, LCD backlights, machine vision applications and more!

- Color choice runs nearly the entire gamut of the visible spectrum, including warm and cool whites, blues and even into UV and infrared wavelengths for specialized use. Bi-color and RGB full color LEDs are also available.

- Fast switching times and efficient, low voltage power consumption for long life – typically more than 100,000 hours!

- Variable brightness levels for easily readable indoor or outdoor applications.

- Popular, low-cost and reliable, cool running and solid state – resistant to external shock.

- Multiple device placements can be connected in series or parallel circuits, run together with switch circuitry or placed on a separate LED layer. Many LEDs are available with built-in resistors!

- Thin profiles can be embedded without the need for embossing.

- Together with a choice of acrylic light pipes, lenses, diffusers, filters, dead-fronts or light guide films with printed or laser-etched reflectors, the LEDs lambertial light distribution can be focused or re-directed where needed. Embossing can also be used to increase the viewing angle if desired.

- Excellent source for Fiber Optic lighting (see below).

EL Panels

Electroluminescent (EL) lampssend DC voltage through an AC converter to excite a phosphorescent material coating between two thin-film printed electrodes, lighting up the molecules.

Benefits & Applications

- Produces a uniform, balanced, soft-glow lighting, best suited for low light or no light environments.

- High efficiency energy conversion consumes relatively little power under normal operations.

- Printable in a variety of patterns, and readily layered under displays, switch graphics, and automotive dashboards.

- Color options are limited by available phosphors, but currently include blue/green, yellow-green, white, blue and orange.

- EL panels generally have a lower price point than Fiber Optic Lighting.

- Requires a DC/AC converter.

- EL panels have a typical half-life of 3K to 8K hours, depending on usage, before beginning to rapidly fade. Intentionally fading or flashing the device in operation can help improve its lifespan, but decay will increase at high voltages or frequencies. Shorter life makes EL panels a poor selection for constant lighting, but often an attractive alternative for short-term or intermittent use.

Fiber Optic Lighting

An optical fiber is a flexible, transparent fiber made by drawing glass (silica) or plastic to a diameter slightly thicker than that of a human hair. Optical fibers typically include a core surrounded by a transparent cladding material with a lower index of refraction. Light is kept in the core by the phenomenon of total internal reflection which causes the fiber to act as a waveguide. Modern fibers have a primary polymer overcoat with a refractive index that is slightly higher than that of the cladding, so that light propagating in the cladding is rapidly attenuated and disappears after only a few centimeters, improving transmission.

For light panels, two or more layers of fiber strands woven into a flat cloth are combined with a reflective backer to form a rectangular light-emitting area. The fibers coming off one end are bundled into a circular ferrule and coupled to one or more LED light sources.

Benefits & Applications

- For large, unbroken fields of evenly dispersed lighting. Since fiber optic lighting is linear in nature, cut-outs will result in ‘dead’ areas to the unlit sides, but careful design and placement of backlit graphics can make this an economical alternative.

- No electrical interference or heat when lit.

- Not affected by extremes in humidity (0% to 100%) or temperature (-40 to +85 deg C).

- Choices of colors, hours of life and power requirements determined by LED light source(s). Intensity of light can be improved with additional layers.

- Thinner, modern constructions help mitigate any effect on tactile response when used with membrane switch panels.

To Boldly Glow…

Emerging technologies continually offer new ideas for achieving traditional backlit effects. Early adopters may suffer some growing pains, but achieving peak efficiency and maximizing cost savings will always be driving factors in the exploration of unusual, untried, or as yet unperfected avenues of development or application. History’s tired and inefficient stop-gap answers like incandescent bulbs and fluorescent tubes may fall by the wayside, but today͛s unprecedented atmosphere of bold innovation and swift technological advancements tease an interesting and ever-promising future for backlighting. Trust that Screenprint/Dow will be offering you the best and brightest!