About Screenprint/Dow

Simple solutions from a single source. That’s a guiding principle at Screenprint/Dow and is something that we constantly strive to deliver to our customers. Some jobs make this goal a true challenge to meet, but with a varied equipment list and talented staff, nearly anything is possible.

As a specialist in the Graphics Printing and Membrane Switch industries, Screenprint/Dow has built a reputation by developing creative and innovative solutions for customer programs and combining an extensive knowledge of material and adhesives with state-of-the-art printing equipment and a wealth of skill. Along the way, we’ve developed ways to extend not only the capabilities of our equipment but also the people on whom we rely each day to exceed customer expectations and our own standards.

Screenprint/Dow’s operations are geared specifically to manufacture products for very demanding applications. A key element is getting down as much information as possible before the actual manufacturing process begins. This may require more work than usual in the initial stages of a project, but such an investment in getting all of the facts straight saves the customer a lot of aggravation and the company a lot of expense.

This often requires extending your Sales team’s skill set to include familiarity with technical jargon, investigative techniques, technical writing or documentation, and more. However, such an investment in salespeople makes a solid impression on customers in the early stages of their projects and ultimately leads to product quality that will secure additional business.

We thrive on the opportunity to explore new and different applications. It’s the best way to learn how we can do our job better, and it’s what makes us grow and will carry us into the future. These are technologies that just go together naturally, so if you have one down already, adding the next isn’t such a leap of knowledge or investment.

Screenprint/Dow’s diversified approach to doing business also extends into the technical area. In addition to screen printing, the firm also relies on offset printing and digital imaging. On occasion, combinations of these processes, such as UV inkjet printing for fine vignettes with screen printing to add metallic inks to simulate foil stamping, are used on the same job to achieve the desired effect. The company can also emboss,over-laminate, and cut by using steel rule dies, hard tools, and laser or digital cutting.

The company has used UV offset since1976. In1981, based on an increase in business and customers looking for fine vignettes, the operation invested in a two-color offset press and then spent two weeks and more out-of-pocket to take the press apart, integrate a UV curing system and put the press back together again. Focusing on stochastic imaging with the offset equipment has allowed the company to produce smaller and flatter dots, reduce imperfections, improve color gamut and saturation, and reduce gray-level limitations and abrupt jumps in tone.

Screenprint/Dow’s screenprinting department includes several single-color presses with IR, UV and LED curing units, and a three-color custom press with a specially configured UV curing unit and a special registration system for medical applications.

Wide-format UV inkjet printing represents the most recent technological expansion at Screenprint/Dow. Four wide format presses are in operation on the production floor, the largest of which can produce prints up to 80in. wide.

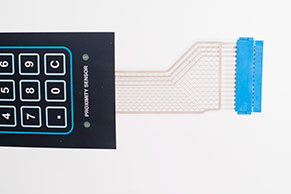

Screenprint/Dow of Wilmington, MA, is an ISO 9001-2015 and ITAR registered custom manufacturer of membrane switches and switch assemblies, membrane keypads with embedded LEDs, rubber keypads and assemblies, EMI/RFI/ESD shielding, graphic overlays, and more. The company has received the Massachusetts Quality Award, a state award based on the Malcolm Baldrige National Quality Awards criteria. The company is privately owned by Walter T. Dow, CEO, who has served and guided the company since its inception in March of 1969. The Company started in a 4000-sq-ft space with 4 or 5 employees and has since grown to 75 on-site employees and a 36,000-sq-ft facility with 34 presses, digital printing, wide format, thermoforming, laser-cutting, and pick-and-place equipment.

Screenprint/Dow supplies products to manufacturers of medical equipment, appliances, fitness equipment, consumer products, laboratory and diagnostic equipment, military and process control solutions.

Screenprint/Dow provides innovative solutions which meet their customer’s needs, expectations and Quality Management systems. As individuals and as a company, they believe that the pursuit of quality requires a culture that is characterized by mutual respect, teamwork, dedication, personal initiative and continual improvement.

The business owes much of its success to a strategy of identifying product niches, making the right purchases at the right times, and embracing new technologies. This tactic has kept Screenprint/Dow a leader in industrial printing for nearly 50 years.

“Screenprint/Dow acts quickly and boldly when we determine that a particular piece of equipment will help us in a certain area, or feel that the marketplace is in need of a particular product or service. We don’t hesitate. By doing that, we’ve given ourselves a great advantage over most of our competition. It also has helped our customers tremendously with new ideas in marketing or product functionality. We’re full service. We make those decisions and get involved in a big, big way.”

With a passion for technology and innovation, CEO Walter Dow prides himself on being part of a company that not only loves new technologies and new ideas but also is the first to bring those technologies in-house and actively participates in the brainstorming of those ideas. As Dow puts it,“We want to be able to do what no one else can do, and we want to be the best there is.”